History of design

April 1998, that’s when F-ONE got into kite design. Right after we successfully designed and marketed the first ever kiteboard.

Looking back into our past, what do we see?

Legendary models

The widely used and only valid kite shape patent

16 years of the most sold kite on the planet

Several international patents

Thousands of samples and test hours

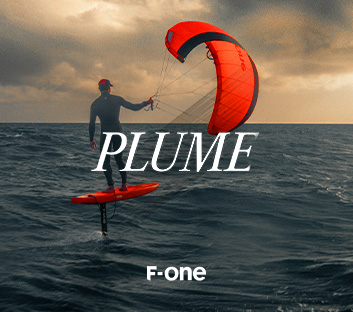

Today, F-ONE is the oldest kitesurfing brand on the market. As our 2023 kite collection is about to be released, we would like to share some of our knowledge with you.

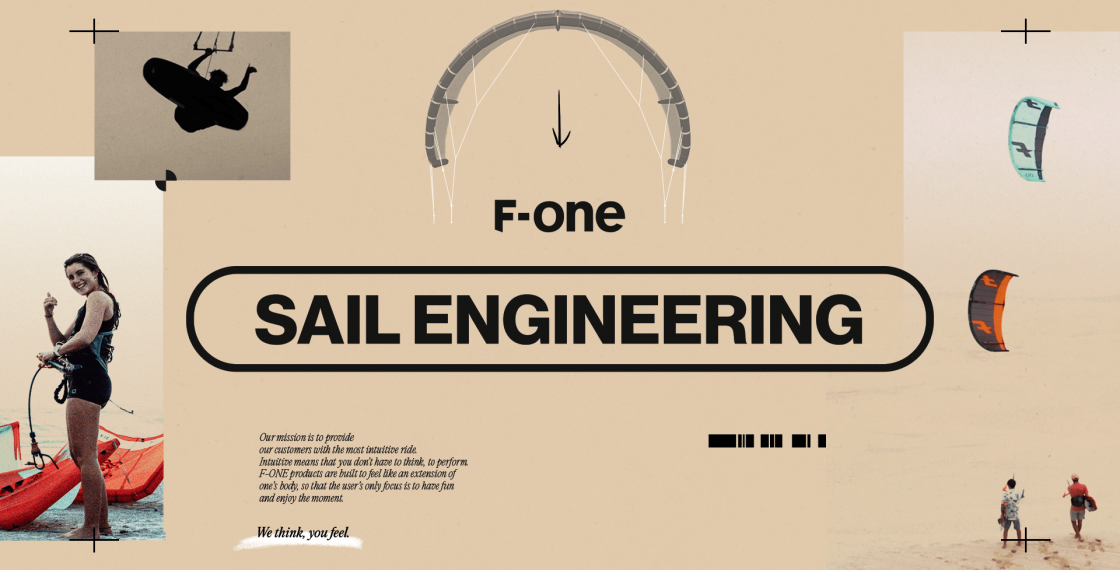

Mission

Our goal is to provide our customers with the most intuitive ride.

Intuitive means that you don’t have to think to perform.

F-ONE products are built to feel like an extension of one’s body, so that the user’s only focus is to have fun and enjoy the moment.

We think, you feel.

Observations

On top of creating the best designs and choosing the best fabrics, the mission of F-ONE’s R&D team is to maintain the kite’s shape. Deformations lead to demanding, unnatural rides. Think instability, rough bar/handle feeling, discontinuous power, unsmooth handling…

Decreased deformation equals a more intuitive ride.

Design and fabrics choice are only one step to building a deformation-less kite.

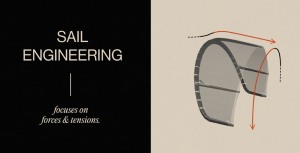

The key is to analyze and understand load tensions to better control our design and its behavior while flying. That is done through sail engineering. When sail design focuses on the shape…

…sail engineering focuses on the forces and tensions applied to this shape.

The science

Here’s one example to illustrate how sail engineering affects your daily sessions:

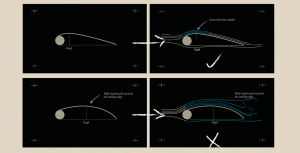

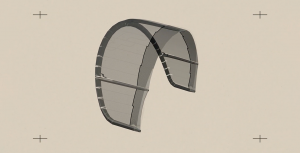

We’re going to focus on the shape that follows the leading edge all the way down to the trailing edge. This is the PROFILE.

The shape, nature and retention of this profile will be one of the most decisive factors to whether you’ll have an intuitive or disturbed ride. Most of it comes down to the draft.

Look at the profile, now spot the area with the most camber. That’s where the wind power will be the most concentrated. This is the DRAFT.

Our kites are designed to keep the draft in the front, towards the leading edge. Conserving the wind power in the front drives the kite forward, leading to many benefits like more stability, speed, comfort, less harness/arms pull, improved wind range…

If the draft slides backward towards the trailing edge, the kite becomes unstable, lacks performances, pulls hard into the harness, loses its depower potential… And thus creates a lot of disturbances for the user.

A strong wind gust, an abrupt move from the user or a powerful kite loop are all forces that tend to deform the kite’s original shape. The only way to make sure that this draft stays where we designed it to stay is through a proper load management, achieved by sail engineering.

Sail engineering is the science of controlling our design and its behavior while flying.

The features below have been created with one goal in mind:

Mastering the kite’s loads to maintain the desired shape, for the longest time.

WARP TENSION LINE

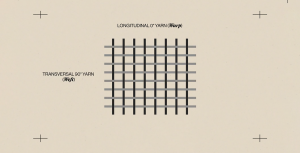

Woven fabrics feature a longitudinal 0° yarn (Warp), and a transversal 90° yarn (Weft). Therefore, a fabric has great strength capacities if you apply tension at 0° or 90° along the yarns. But it will deform and stretch when tension is applied at, let’s say, 45°.

LOAD CONTROL PANELING

When engineering the load control paneling, we make sure that fabrics panels are warp/weft oriented, meaning that the load path runs through the yarns. Fabric and seams are then in the best position to receive tensions and maintain the original kite shape.

STAGGERED SEAMS

Most of the kite’s back lines tension is distributed through the trailing-edge panels and seams. As seams are significantly stiffer than the fabric they join, they tend to strain under loads and therefore deform the profile. The staggered seams break that line of tension by balancing the stiffness between seams and cloth, which helps distributing the load over a wider area and maintaining the original shape even under high loads.

FABRIC WEIGHT MANAGEMENT

Our sails feature four different cloth weights, from 52 up to 155gr/m². Sail engineering allows us to control our shape and drive load tensions without using heavy fabrics or bulky designs, therefore we can reduce fabric’s weight and use. It results in a lighter, optimized kite.

Benefits

The benefits of our sail engineering are numerous while riding:

Reduced disturbances

Increased performance and wind range

Improved stability and control

Increased sense of security

Optimized weight

Improved durability

Having a better load control, the kite maintains its shape over its lifespan without stretching and will keep performing for much longer over the years.

When choosing F-ONE, you’re not only choosing breakthrough designs and top-notch fabrics. You’re choosing a brand that puts sail engineering at the service of your ride.